PRE - ENGINEERED BUILDINGS & HOT ROLLED BUILDINGS

Over view

Fabrication

Saham samhan has a total site area of 3000 sq/m including 2,000 sq/m of covered fabrication area and 1000 sq/m of storage area with the capacity to produce in excess of 25,000t of fabricated steelwork per year. Products include Pre-Engineered buildings + accessories / cold form C and Z profiles / Sheeting and Decking / insulated Panels / Hot rolled structures / Built up Heavy Plate work / Complex projects.

Fabrication is undertaken in a controlled environment with direct links from the engineering and production control departments to the CNC preparation machines. This in an integral part of saham samhan quality and monitoring systems.

Structural Design

Saham samhan is capable of designing all kind of high complex steel structures such as high rise buildings, airport terminal buildings and industrial structures for process, petroleum and power plant industries. Our team of design engineers are highly qualified and specialized in steel design and analysis with latest software environment and highly experienced with all American, British, European and other international design standards

Erection

Since the formation of Saham samhan Building Systems in 2004, Saham samhan Building Systems has developed an excellent reputation and strong presence as one of the regional’s Saham samhan fabricator and erector. Our research and development team are striving to deliver the best solution in the steel industry.

Saham smahan range of erection capabilities includes all kind of steel structures (low, medium and high complexity) such as:

- Warehouses and distribution centers

- Airplane hangars

- Airport structures

- Showrooms and production facilities

- Shopping centers

- Power plants

- High rise buildings

- Structures

Hot Rolled Steel Structures

Saham samahan provides top-of-the-line structural steel fabrication services. Saham samhan works with the best designers and engineers to ensure that all projects meet high standards of excellence and to provide excellent service. Our state of art steel fabrication facility is equipped with the latest technology of CNC Machines in Steel Structure Fabrication. We are capable of taking on any heavy-industrial, infrastructure or commercial projects, ranging in scale and complexity

Advantages of Hot Rolled Steel

- The Hot rolled manufacturing process is cheaper than the other manufacturing process.

- Hot rolled steel is ideal where dimensional tolerances aren’t as important as overall material strength.

- Better mechanical properties.

- The change in the microstructure of the material increases the ductility and toughness of the material.

- Because of how high the temperatures are, hot rolled steel is more malleable.

- Hot rolling can improve the processing performance of metals and alloys.

Pre-engineered Buildings

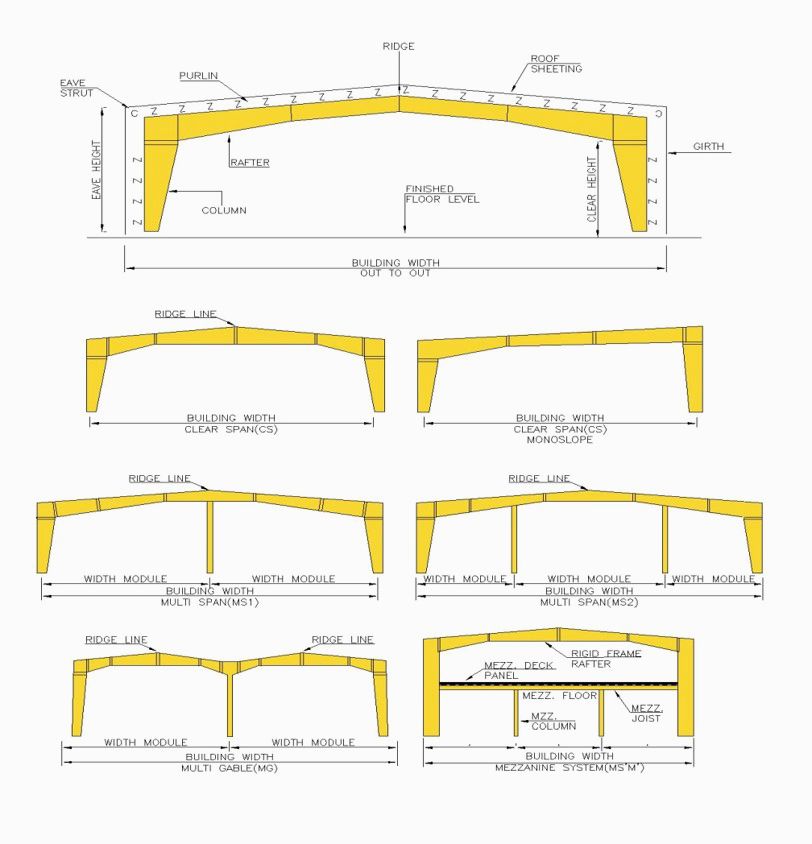

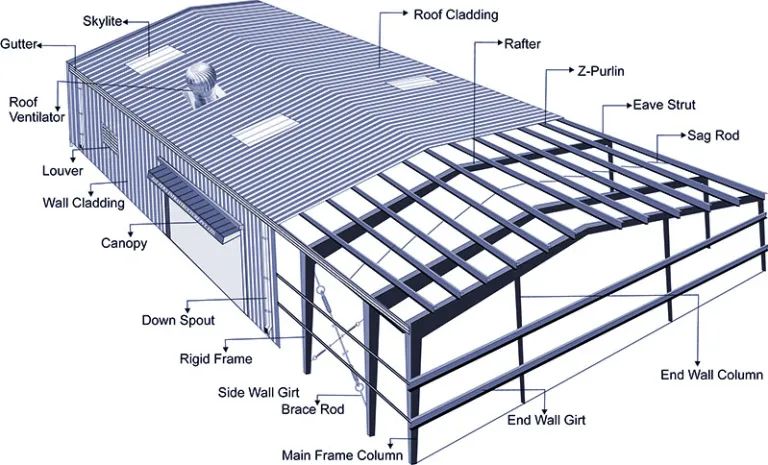

Primary Framing Systems

Saham samhan trading & cont. are optimized to meet specific requirements of each client. Commonly used primary framing systems are shown below. All frames shown are symmetrical about the ridge line. Framing systems asymmetrical about the ridge line, multi-span systems with unequal width modules and frames outside the ranges shown are possible, but require special study.

Primary framing consists of all structural elements which transfer load to the foundation and comprises of: • Intermediate frames • End wall frames • Wind bracings • Crane brackets • Mezzanine beams and joists

Primary framing is manufactured such that only bolted connections are required

Intermediate Frames

Intermediate frames consist of built-up welded members. For multi-span frames, intermediate columns are either pipe sections, hot-rolled profiles or built-up welded profiles. Frames are complemented by flange bracing, connection bolts and anchor bolts. Column bases are usually pinned. Fixed connections, if required as per design, can also be provided.

End wall Frames

End wall frames consist of either built-up welded, hot-rolled or cold-rolled columns which support a cold-formed or hot-rolled rafter. Frames are complemented by connection bolts, anchor bolts and wind bracing, if required.

Wind Bracing

Wind bracing provides longitudinal stability for the building. It consists of cross-bracing located in the roof and side walls in one or more bays depending on the quantity of load and the length of the building. When required, cross-bracings can be replaced by wind portal frames or by fixed base wind columns located adjacent and connected to the mainframe columns.

Mezzanines in Buildings

Intermediate mezzanine floors are possible in metal buildings. Mezzanine floors can be provided in complete or partial area in pre-engineered buildings to suit loading requirements for office and storage. Mezzanine floors consist of steel decks, supported by joists framed to the mezzanine beams. Main mezzanine beams normally run across the width of the building and are located under the main rafters while joists run parallel to the length of the building. The top flange of the joists fit immediately below the top flange of the mezzanine beam.

The economy of the mezzanine floor is affected by the applied load and support column spacing. Multi-level equipment platforms, catwalks, staircases etc. can be accommodated, if complete data is available.

Vision

Completed projects

Mission

To supply high-quality steel products, providing related services and solutions to a worldwide client base while utilizing innovative technologies within an environment of motivated employees, focused on continuous improvement